Predetermined Overhead Rate Formula How to Calculate?

Therefore, they use labor hours for the apportionment of their manufacturing cost. A number of possible allocation bases are available for the denominator, such as direct labor hours, direct labor dollars, and machine hours. If a job in work in process has recorded actual machine hours of 140 for the accounting period then the predetermined overhead applied to the job is calculated as follows. A predetermined overhead rate is calculated before the start of an accounting period. One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate. A business can calculate its actual costs periodically and then compare that to the predetermined overhead rate in order to monitor expenses throughout the year or see how on-target their original estimate was.

Double Entry Bookkeeping

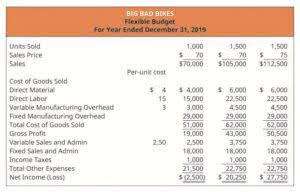

According to a survey 34% of the manufacturing businesses use a single plant wide overhead rate, 44% use multiple overhead rates and rest of the companies use activity based costing (ABC) system. Once an overhead rate is calculated using the given formula, it’s absorbed in the cost card of the business using the actual level of the activity. At the end of the accounting period, the actual indirect cost is obtained and compared with the absorbed indirect. payroll By using the predetermined rate product costs and therefore selling prices can be calculated quickly throughout the year without the need to wait for actual overheads to be determined and allocated. In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows.

Predetermined Overhead Rate Basis

Different businesses have different ways of costing; some would use the single rate, others the multiple rates, while the rest may make use of activity-based costing. The company, having calculated its overhead costs as $20 per labor hour, now has a baseline cost-per-hour figure that it can use to appropriately charge its customers for labor and earn a profit. That is, the company is now aware that a 5-hour job, for instance, will have an estimated overhead cost of $100. The predetermined overhead rate is a powerful tool for cost management, but it requires careful estimation and periodic review.

Sales and production decisions based on this rate could be faulty

If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be over applied by 25 (1,600 – 1,575). The overhead will be allocated to the product units at the rate of 10.00 for each machine hour used. Again the actual overhead at the end of the accounting period is 1,575 and the overhead is said to be under applied by 81 (1,494 – 1,575) as shown below. Two companies, ABC company, and XYZ company are competing to get a massive order that will make them much recognized in the market. This project is going to be lucrative for both companies but after going over the terms and conditions of the bidding, it is stated that the bid would be based on the overhead rate. This means that since the project would involve more overheads, the company with the lower overhead rate shall be awarded the auction winner.

Businesses monitor relative expenses by having an idea of the amount of base and expense that is being proportionate to each other. This can help to keep costs in check and to know when to cut back on spending in order to stay on budget. In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate. The predetermined overhead rate formula can be used to balance expenses with production costs and sales. For businesses in manufacturing, establishing and monitoring an overhead rate can help keep expenses proportional to production volumes and sales. It predetermined overhead rate can help manufacturers know when to review their spending more closely, in order to protect their business’s profit margins.

Prior to the start of the accounting year, JKL Corp calculates the predetermined annual overhead rate to be used in the new year. JKL’s profit plan for the new year includes $1,200,000 as the budgeted amount of manufacturing overhead. JKL allocates the manufacturing overhead based on the normal and expected number of production machine hours which are 20,000 for the new year. Therefore, the JKL’s predetermined manufacturing overhead rate for the new year will be $60 ($1,200,000/20,000) per production machine hour.

- Detailed cost analysis helps to estimate the cost of overheads with accuracy.

- If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

- If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be under applied by 75 (1,500 – 1,575) as shown in the table below.

- This complexity is driven by different factors, including but not limited to common activity for multi-products and a greater number of supportive activities for the production.

- Hence, the fish-selling businesses need to monitor the seasonal variations and adjust the cost pattern of the products.

- This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit.

Predetermined overhead rate

- The predetermined overhead rate is calculated by dividing the estimated manufacturing overhead by the estimated activity base (direct labor hours, direct labor dollars, or machine hours).

- The use of multiple predetermined overhead rates may be a complex and time consuming task but is considered a more accurate approach than applying only a single plant-wide rate.

- According to a survey 34% of the manufacturing businesses use a single plant wide overhead rate, 44% use multiple overhead rates and rest of the companies use activity based costing (ABC) system.

- If the absorbed cost is more than the actual cost, an adjusting entry is passed to reduce the expenses.

- For instance, it has been the traditional practice to absorb overheads based on a single base.

- The comparison of applied and actual overhead gives us the amount of over or under-applied overhead during the period which is eliminated through recording appropriate journal entries at the end of the period.

So, a more precise practice of overhead absorption has been developed that requires different and relevant bases of apportionment. On the other hand, if the business wants to use actual overheads, it has Insurance Accounting to wait for the end of the month and get invoices in hand. So, it may not be a good idea with perspective to effective business management. In addition to this, project planning can also be done with the use of an overhead rate. It’s because it’s an estimated rate and can be predicted at the start of the project. This complexity is driven by different factors, including but not limited to common activity for multi-products and a greater number of supportive activities for the production.

This Post Has 0 Comments